Partnerships with purpose

Our global team of experts work closely with our partners to ensure a successful transition to better materials. We partner with a range of businesses including brands, manufacturers and convertors. Working together ensures everyone benefits from shared knowledge from testing and trials through to launching in market. Xampla has a licensing business model to bring our technology to different industries, geographies, and markets with our partners.

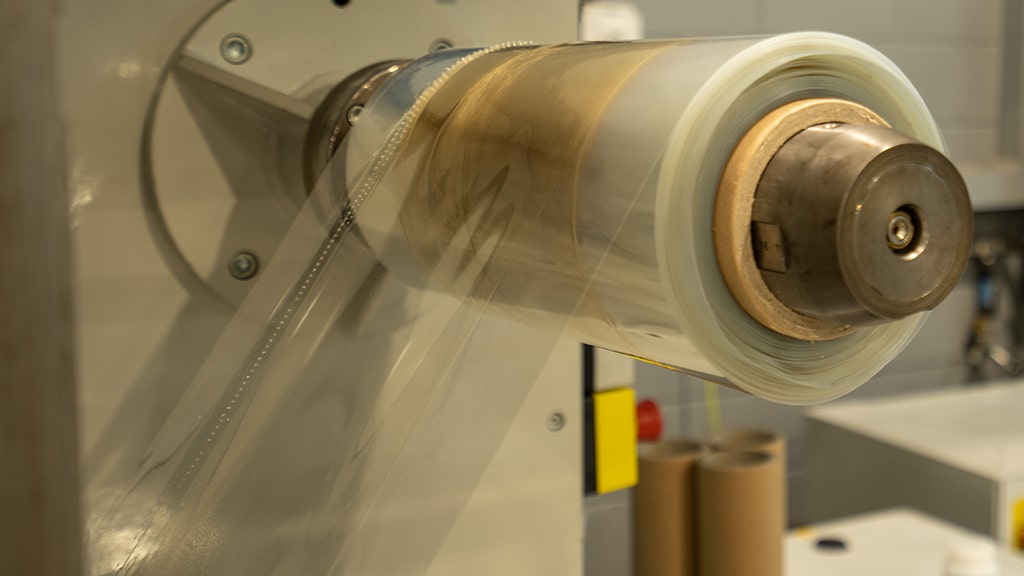

Morro™ Coating at scale

2M Group of Companies: licence partner

With Xampla’s licensing approach, we work with global manufacturing companies to scale our breakthrough materials using their extensive operational expertise. Our plastic-free and fully biodegradable Morro Coating for paper packaging is available at scale with our licence partner, 2M Group of Companies. Together with 2M, we have accelerated growth of Morro Coating within UK and EU markets and are delivering commercial sales with global packaging manufacturers. Uniting our expertise with 2M’s manufacturing capabilities, our partnership could replace up to 25,000T of single use plastic coating over the next 5 years.

New materials, existing processes

Our team understands industry and that is why we have developed our technology to ‘drop-in’ to existing supply chains and we will work with you to ensure a smooth transition. This means that there is no need to invest in new machinery or equipment. Working with you, we can match our patented technology to your existing equipment meaning lower costs, greater choice, and a faster route to success. We don’t believe in restriction; we believe in innovation.

Working in partnership with the world's largest organisations